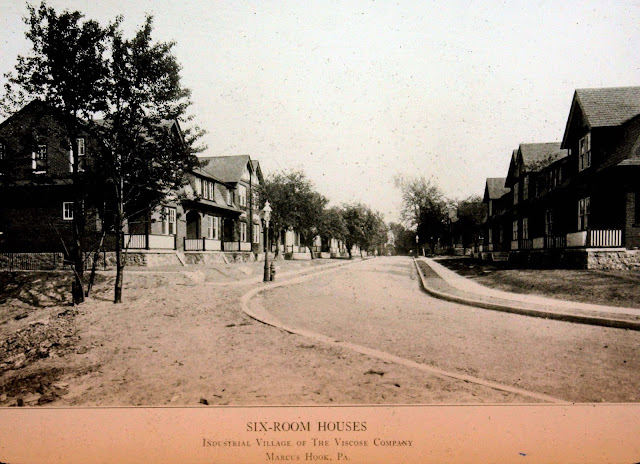

An advertisement for the Viscose Village in Marcus Hook from about 1913

Note: The Viscose Plant originally made artificial silk and later rayon. The village was built in 1912/1913 to accommodate the workers. A Historical marker marks the village today

TO BUILD 300 HOUSES IN MARCUS HOOK

American Viscose Co. Will Also Double Capacity of Plant

Dr. C. A. Ernst, the manager of the Marcus

Hook plant of the American Viscose Company announced this morning that the

plans for a new addition to their present plant which would double its capacity

and three hundred dwellings had been completed.

The improvements, including buildings and machinery will cost

approximately $1,000,000.

Ballinger and Perrott architects of

Philadelphia, have completed the plans.

James Clayton, a constructing engineer of England, who is connected with

the English and parent branch of the American Viscose Company, has arrived here

and will personally oversee the work.

The houses will be commenced in the near future and the mill addition,

which will cost about $100,000 will be started immediately.

The plant now employs more than 1,000

people in the manufacture of artificial silk.

When the improvements to the mills are completed it will require a force

of two thousand persons. The 300

dwellings are designed to help to care for the increased number of employees.

William Provost, Jr., a Chester

contractor, recently finished a $10,000 addition to this plant. The building, which is known as a

“mercerizing cellar” is a one-story structure, eighty feet by thirty-five feet,

of reinforced concrete, with a slag roof and electric lighted throughout.

Now that the plans for the $100,000

building have been completed by the architect, bids will be asked and the work

of building commenced as soon as possible.

The dwelling houses will be located between the plant and Marcus Hook

proper and will be erected upon the tract purchased some time ago by the

company for this purpose.

The $100,000 annex to the main factory

will be a duplicate of the present one story portion or wing of the Marcus Hook

works. It will be four hundred feet long

by one hundred and twenty feet wide, and one story in height. The building will be of brick mill

construction and will be fireproof. In

this building will be included the spinning, washing, twisting and reeling

departments.

The equipping of this second and larger

building will be a much more expensive proposition for the American Company to

handle than the mere erection of the building.

About one hundred and twenty machines will be installed in the new

building. About one hundred and twenty

machines will be installed in the new building when it is completed. The approximate cost of the machinery was

placed at $400,000 by Dr. C. A. Ernst, the general manager of the American

Viscose Company, when seen at his office.

This machinery will be mainly for the handling of the spinning, twisting

and reeling work.

The power to operate this new mill will be

electric and will be furnished by the Beacon Light Company of this city. The Beacon Company is furnishing the American

Company with all of its operative power at this time.

With the completion of the enlargement of

the works now under way the company will furnish employment for one thousand

additional workmen. Approximately one

thousand people are now in the employ of the company. This means the doubling of the capacity of

the Marcus Hook plant within the next year.

The company is solicitous of the health

and the welfare of its employees. A

dispensary is connected with the plant and a trained nurse, a graduate of the

Chester Hospital, is in constant attendance.

While most of the accidents at this plant are of a minor natured, all

those who suffer from lacerations, contusions, abrasions, acid burns, etc., are

given immediate attention.

No comments:

Post a Comment